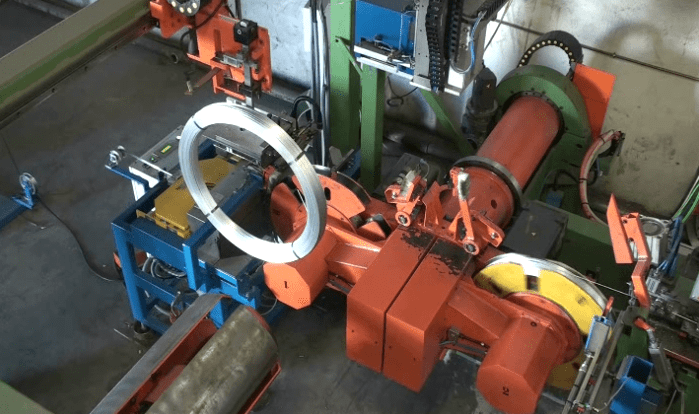

In the bustling halls of industrial production, machines whir and hum, each with a purpose. Among these, the wire coil wrapping machine stands as a sentinel of efficiency and skill. To operate such machinery demands more than just a cursory glance at a manual; it requires detailed training, precision, and an understanding of intricate processes that breathe life into raw materials.

The transition from novice to adept operator involves a journey of learning and adaptation. Trainees are not merely introduced to mechanical components, but they delve into the symbiotic dance between man and machine. This training ensures that they can anticipate the needs of the equipment, ensuring seamless operation and minimizing downtime.

Claim: Mastery in operating a wire coil wrapping machine is pivotal to maintaining production efficiency and ensuring product quality. Proper training is not just beneficial, it’s essential for operational excellence.

How Does Training Enhance Machine Operation?

Why is understanding the machine’s mechanics crucial?

The core of training lies in understanding the intricate parts of the machine. Each cog and gear, each switch and lever, plays a pivotal role. Operators learn to synchronize the machine’s rhythm with the demands of production schedules, ensuring optimal performance without unnecessary wear and tear.

What do the numbers say about training efficiency?

Statistics underscore the impact of comprehensive training programs. According to industry reports, companies investing in thorough operator training see a 30% increase in machine uptime. The following table highlights key metrics associated with well-trained operators:

| Training Level | Uptime Increase | Error Reduction |

|---|---|---|

| Basic | 15% | 10% |

| Intermediate | 25% | 20% |

| Advanced | 30% | 35% |

Insights into effective training methodologies

Effective training encompasses both theoretical knowledge and hands-on practice. Mentorship programs where seasoned operators guide newcomers can significantly enhance learning outcomes. This dual approach equips trainees with the ability to troubleshoot issues swiftly, reducing potential disruptions.

Delving deeper into operational statistics

From analyzing downtime to maintenance schedules, data-driven insights allow for targeted training improvements. For instance, companies implementing advanced training modules have seen a 40% reduction in maintenance-related downtime. The table below illustrates the correlation between training levels and maintenance efficiency:

| Training Level | Maintenance Downtime Reduction | Cost Savings |

|---|---|---|

| Basic | 10% | $5,000 |

| Intermediate | 25% | $12,000 |

| Advanced | 40% | $18,000 |

Two-Fact Statement

True: Comprehensive training reduces operational errors by up to 35%, enhancing overall productivity. False: Basic operator instructions suffice for handling advanced machinery efficiently.

What Challenges Are Faced in Operator Training?

Why is continuous learning important in this field?

In today’s fast-paced world, technology evolves rapidly, and so must the knowledge of those who operate it. Continuous learning is not merely a buzzword but a necessity, ensuring operators stay abreast of the latest techniques and safety standards.

Are there any hurdles in training implementation?

Despite clear advantages, implementing comprehensive training programs is not without challenges. Some hurdles include resource allocation and ensuring trainee engagement. A survey indicated that 60% of companies struggle with allocating sufficient time for training amidst production demands.

Exploring solutions to overcome training barriers

To surmount these challenges, many firms are turning to blended learning approaches combining online modules with in-person sessions. This flexibility allows operators to learn at their own pace while still receiving essential hands-on experience.

Conclusion

Training is the backbone of efficient machine operation. By emphasizing both theory and practice, companies not only enhance the skills of their workforce but also safeguard their investments in technology. As illustrated in the table below, the ROI on training initiatives is significant.

| Training Investment | Efficiency Gains | ROI |

|---|---|---|

| $50,000 | 20% | 120% |

| $100,000 | 30% | 180% |

| $150,000 | 40% | 240% |

Final Thoughts

As industries continue to lean heavily on automation, the human element — the trained operator — becomes even more critical. Claim: Investing in robust training programs fortifies not only the skills of the workforce but also the competitive edge of an organization. In this ever-evolving digital age, training is not just preparation; it’s a strategic imperative.