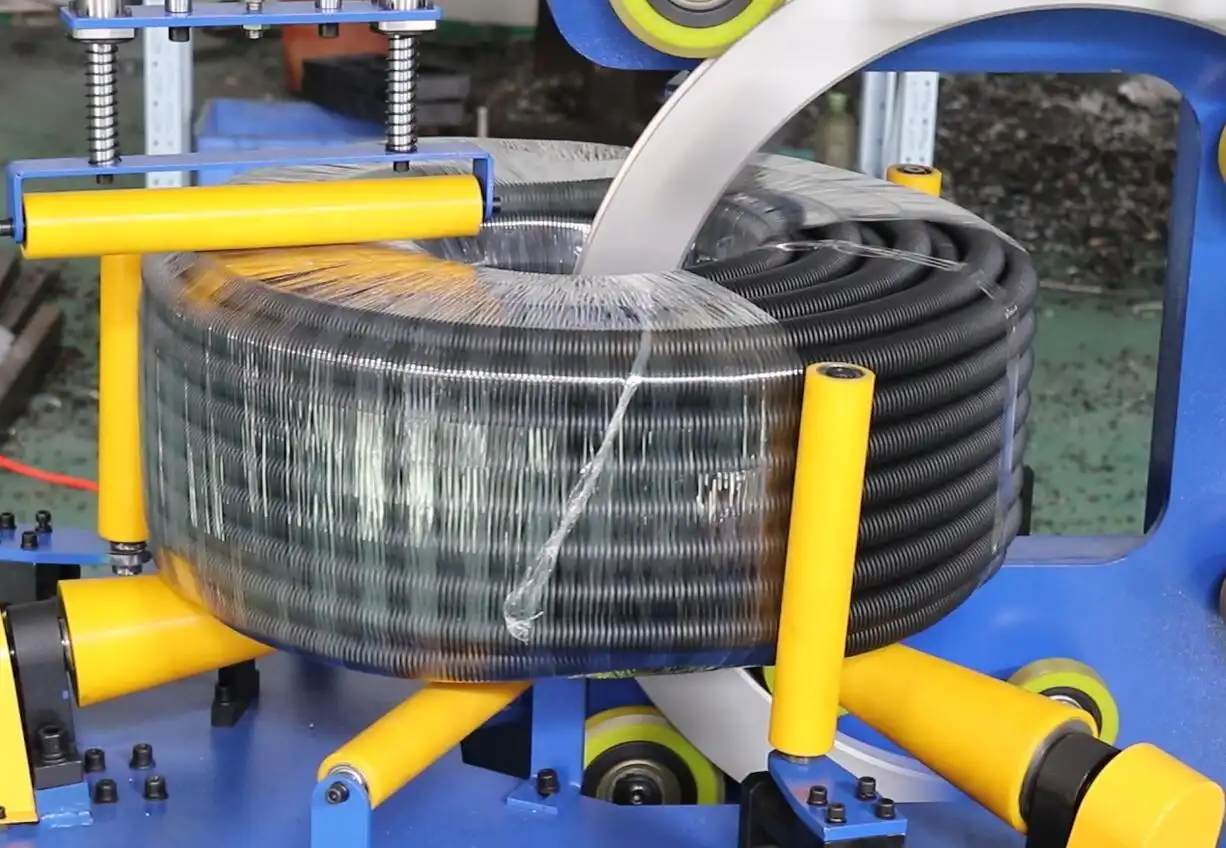

In the industrial world, the efficiency of operations is often hinged on the right equipment. A pivotal piece of machinery in many manufacturing sectors is the pipe coil wrapping machine. As demand grows, so does the complexity involved in choosing the ideal model to suit diverse needs. Surprisingly intricate, this decision process requires an understanding of various factors that contribute to a machine’s performance and reliability.

The market offers a myriad of options, each claiming superiority in functionality, durability, and cost-effectiveness. Navigating through these choices can be daunting without a clear understanding of what defines excellence in a pipe coil wrapping machine. Transitioning from confusion to clarity necessitates a strategic approach, one that is informed by both industry standards and specific operational requirements.

Claim: Comprehending the best practices for selecting a pipe coil wrapping machine is essential for optimizing efficiency and ensuring long-term operational success.

Why Is Understanding Your Needs Crucial?

Assessing Operational Requirements: How Should You Start?

A thorough assessment of your operational needs forms the cornerstone of selecting the right machine. Begin with analyzing the types and sizes of pipes you frequently handle. Consider the volume of production—are you operating on a small scale or handling mass production? The answers to these questions dictate the specifications required in a machine, influencing factors like speed, automation level, and load capacity.

Data-Centric Insights on Machine Specifications

| Model | Max Speed (m/min) | Load Capacity (kg) | Automation Level |

|---|---|---|---|

| Model A | 30 | 500 | High |

| Model B | 20 | 300 | Medium |

| Model C | 25 | 400 | Low |

What Key Features Should You Look For?

When evaluating different models, prioritize features like ease of operation, energy efficiency, and maintenance requirements. Machines with advanced controls and user-friendly interfaces reduce training time and enhance productivity. Energy-efficient models not only reduce operational costs but also align with sustainability goals. Additionally, consider machines with minimal maintenance demands to decrease downtime and repair expenses.

Analyzing Cost Against Performance

| Machine | Initial Cost ($) | Annual Maintenance Cost ($) | Expected Return on Investment (Years) |

|---|---|---|---|

| Basic Model | 10,000 | 500 | 3 |

| Premium Model | 20,000 | 300 | 5 |

| Advanced Model | 15,000 | 400 | 4 |

Two-Fact Statement

- True Fact: Energy-efficient pipe coil wrapping machines can reduce operational costs by up to 30%.

- False Fact: All pipe coil wrapping machines require the same level of operator expertise to manage effectively.

How Do You Evaluate Manufacturer Support?

Manufacturer Reputation: What Should You Consider?

Evaluating the manufacturer’s reputation is as crucial as assessing the machine itself. A reputable manufacturer provides assurance of quality and reliability. Check for customer reviews and industry certifications. These indicators help gauge the manufacturer’s commitment to quality and customer satisfaction. Moreover, explore the range of customer support services available, from installation assistance to post-sale support.

Service Agreements and Warranties

| Manufacturer | Warranty Period (Years) | Service Agreement Options |

|---|---|---|

| Manufacturer X | 2 | Comprehensive |

| Manufacturer Y | 3 | Limited |

| Manufacturer Z | 5 | Full Coverage |

Understanding After-Sales Support: Why Is It Important?

After-sales support distinguishes exceptional manufacturers from average ones. This includes timely delivery of spare parts, availability of technical support staff, and prompt resolution of issues. Many businesses overlook the importance of strong after-sales support, which can lead to prolonged downtimes and increased costs. Ensuring robust support systems are in place enhances the overall user experience and longevity of the machine.

Conclusion

Choosing the right pipe coil wrapping machine is a complex yet rewarding task when approached with the right knowledge and strategy. By understanding operational needs, evaluating key features, analyzing cost-performance balance, and considering manufacturer support, businesses can make informed decisions that enhance efficiency and profitability. Armed with these insights, industries can confidently invest in technology that propels them towards greater heights.

Final Claim: Implementing best practices in selecting pipe coil wrapping machines empowers businesses to achieve unparalleled efficiency and operational excellence.