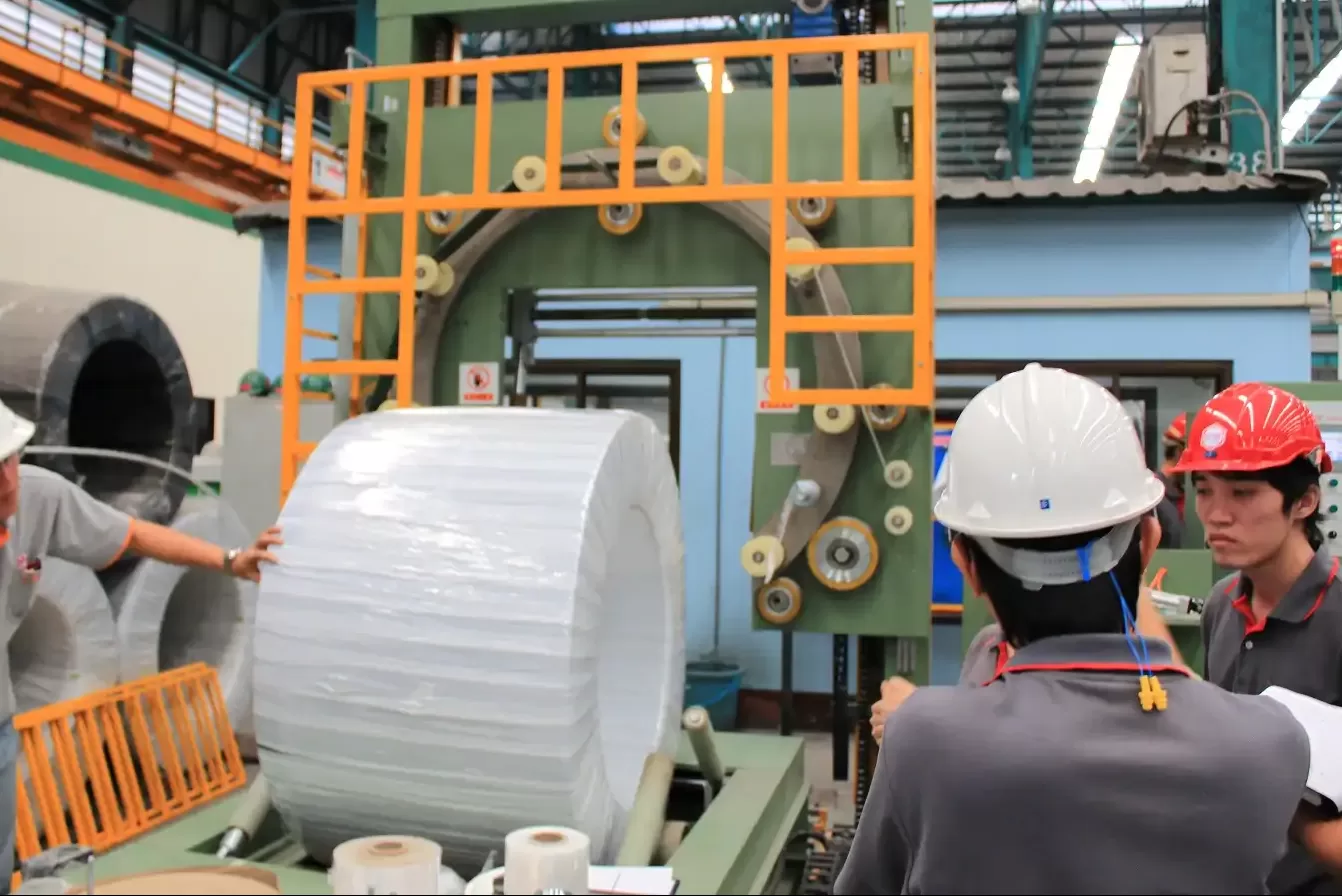

In the dynamic world of industrial manufacturing, the significance of each component in the production line cannot be overstated. When it comes to enhancing efficiency and ensuring quality, the machines chosen can make all the difference. Among these pivotal tools is the aluminum coil wrapping machine, a device that plays a crucial role in packaging and protecting coils during transport. The decision to invest in such machinery is not made lightly. It requires substantial preparation, foresight, and understanding of the intricate details involved in the procurement process.

To navigate the complexities inherent in this significant purchase, it’s essential to explore the project preparation stage. This phase is where strategic planning meets practical application, aiming to align the company’s objectives with the capabilities of the new equipment. By understanding the factors at play, decision-makers can ensure a seamless transition from concept to execution.

Claim: Proper preparation in purchasing an aluminum coil wrapping machine is paramount to achieving both operational excellence and financial prudence.

What are the Key Considerations when Preparing for an Aluminum Coil Wrapping Machine Purchase?

Evaluating Your Manufacturing Needs: Why Does It Matter?

The first step in preparing for the acquisition is a thorough evaluation of the manufacturing needs specific to your operation. Understanding the precise requirements of your production line ensures that the selected machine will integrate smoothly into existing workflows. Without this clarity, companies risk investing in equipment that either underperforms or overextends capabilities, leading to inefficiencies.

Data Insights: How Do Current Usage Metrics Support Decision-Making?

Consider existing data metrics, which provide a snapshot of current production demands. For instance, if a facility processes 1,000 coils monthly, the machine must handle at least that volume efficiently. Below is a table illustrating typical coil processing requirements:

| Production Volume | Machine Capacity Required | Potential Bottlenecks |

|---|---|---|

| 500 coils/month | Medium Capacity | Minor Delays |

| 1,000 coils/month | High Capacity | Occasional Overruns |

| 2,000 coils/month | Ultra Capacity | Frequent Congestion |

How Can Manufacturers Match Machine Features with Production Goals?

Once needs are assessed, attention must turn to machine features. Each model offers unique advantages—such as speed, wrap precision, and automation level—that must be measured against production goals. A realistic evaluation of these factors helps identify models that promise to elevate production standards without introducing unnecessary complexity.

Diving Deeper: What Numerical Data Supports Feature Comparison?

Choosing the right features involves scrutinizing technical specifications. Evaluating data such as wrapping cycle times and energy consumption can reveal insights into machine efficiency. Here’s a table comparing key features across popular models:

| Machine Model | Cycle Time (sec) | Energy Use (kWh) | Automation Level |

|---|---|---|---|

| Model A | 20 | 1.5 | High |

| Model B | 30 | 1.2 | Medium |

| Model C | 25 | 1.8 | Advanced |

Two-Fact Statement: What’s True and What’s Not?

Fact 1: An aluminum coil wrapping machine can reduce packaging time by up to 50% through automation advancements.

Fact 2: All aluminum coil wrapping machines operate at the same efficiency level regardless of brand or model. (False – Efficiency varies greatly among different brands and models, influenced by design and technology used.)

Why is Vendor Selection Crucial in the Project Preparation Stage?

Vendor Research: What Should You Look For?

Vendor selection is a critical component of the preparation stage. A well-chosen vendor will provide not only the machine but also ongoing support essential for long-term success. It’s vital to research potential vendors thoroughly, assessing their industry reputation, customer service records, and technological advancements.

Comparative Snippet: How Do Vendor Offerings Differ?

Examining vendor offerings reveals variations that can impact the purchase decision. Factors such as warranty terms, service packages, and customization options should be carefully compared. Here’s a comparative table of leading vendors:

| Vendor | Warranty Period | Service Package | Customization Options |

|---|---|---|---|

| Vendor X | 2 Years | Comprehensive | Limited |

| Vendor Y | 1 Year | Standard | Extensive |

| Vendor Z | 3 Years | Premium | Customizable |

How Does Vendor Support Influence Operational Success?

After narrowing down vendor choices, delve into the support services they offer. Effective post-purchase support ensures minimal downtime and smooth machine integration. Vendors that offer comprehensive training sessions and maintenance packages typically provide better value, facilitating a quicker adaptation period and maximizing operational efficiency.

Conclusion: What are the Ultimate Takeaways from the Preparation Stage?

In conclusion, the preparation stage for acquiring an aluminum coil wrapping machine is multifaceted, involving meticulous planning and informed decision-making. Companies must balance immediate operational needs with future growth potential, ensuring the chosen machine aligns with both current requirements and long-term objectives. A detailed examination of both internal production goals and external vendor capabilities is essential.

The following table summarizes essential preparation steps:

| Preparation Step | Key Considerations | Outcome |

|---|---|---|

| Needs Assessment | Volume and Capability | Defined Requirements |

| Feature Evaluation | Technical Specifications | Optimal Machine Selection |

| Vendor Selection | Reputation and Support | Trusted Partnership |

Ultimately, the success of the investment hinges on careful preparation and strategic alignment with business goals. Claim: By committing to thorough research and comprehensive evaluation, businesses can secure a machine that not only meets but exceeds expectations, driving productivity and profitability forward.