In the bustling world of industrial production, choosing the right equipment can make or break efficiency and output. One such critical decision is selecting the ideal copper coil packing machine. With numerous options available in the market, understanding what to look for can greatly impact operational success.

The process of choosing a copper coil packing machine can be daunting, given the plethora of models, each boasting unique features and capabilities. It’s essential to navigate this complex landscape with an informed perspective to ensure a choice that aligns with specific business needs.

Claim: Choosing the right copper coil packing machine is pivotal in maximizing productivity, ensuring product integrity, and reducing operational costs.

What factors should you consider when selecting a copper coil packing machine?

Understanding Key Features and Specifications

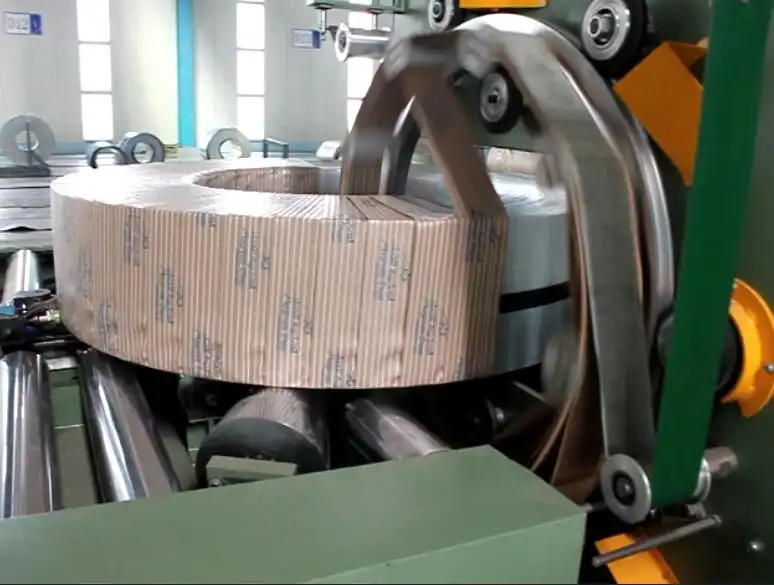

The first step in selecting the right copper coil packing machine involves understanding its key features and specifications. Prioritize machines with robust construction, adaptability to various coil sizes, and ease of maintenance. Machines equipped with advanced technology offer enhanced precision and speed, crucial for meeting high production demands.

Market Overview: A Glimpse Into Statistics

The global market for copper coil packing machines has seen significant growth, with projections indicating an annual increase of 6% in demand over the next five years. Table 1 provides a breakdown of the leading manufacturers and their market shares.

| Manufacturer | Market Share (%) |

|---|---|

| Company A | 20 |

| Company B | 15 |

| Company C | 12 |

Insights into Efficiency and Output

Selecting the right machine directly correlates with increased efficiency and output. Advanced machines integrate seamlessly with existing systems, offering automated solutions that minimize human error and downtime. This synergy results in a consistent and reliable packing process, enhancing overall productivity.

The Role of Cost and ROI

Cost is a significant factor in the decision-making process. While initial investment might seem high, the return on investment (ROI) often justifies the expense. Table 2 illustrates the relationship between machine cost and potential ROI over a three-year period.

| Machine Cost ($) | Projected ROI (%) |

|---|---|

| 50,000 | 25 |

| 75,000 | 30 |

| 100,000 | 40 |

Two-Fact Statement: Myths and Truths

Fact 1: All copper coil packing machines require extensive manual operation. False – Many modern machines are highly automated, reducing the need for constant supervision.

Fact 2: Investing in a quality packing machine can reduce long-term costs significantly. True – Despite higher upfront costs, efficient machines decrease waste and energy consumption, saving money in the long run.

How does technology influence the selection of packing machines?

Technological Advancements and Their Impact

Technology plays a crucial role in the evolution of packing machines. Innovations such as IoT integration, real-time monitoring, and predictive maintenance have transformed traditional machines into intelligent systems. These advancements improve machine lifespan and performance, making them a wise investment for forward-thinking businesses.

Technological Trends: A Snapshot

Data suggests that 70% of new packing machines now feature IoT capabilities. Table 3 provides insights into the adoption rates of different technological features in modern packing machines.

| Feature | Adoption Rate (%) |

|---|---|

| IoT Integration | 70 |

| Predictive Maintenance | 60 |

| Real-time Monitoring | 50 |

Enhancing Efficiency Through Technology

The integration of technology enhances efficiency by streamlining operations and facilitating proactive maintenance. Machines equipped with these technologies alert operators to potential issues before they escalate, minimizing downtime and maintaining uninterrupted production cycles.

Conclusion: Navigating the Future of Packing Technology

The future of copper coil packing machines lies in embracing technological innovations that refine processes and boost productivity. Businesses that incorporate advanced machines not only enhance operational efficiency but also position themselves as industry leaders. Table 4 summarizes the key takeaways from integrating technology into packing solutions.

| Benefit | Impact |

|---|---|

| Reduced Downtime | 25% increase in productivity |

| Enhanced Accuracy | 30% reduction in material waste |

| Improved Monitoring | Real-time data access |

In conclusion, selecting the right copper coil packing machine is a strategic decision that balances cost, technology, and efficiency. By understanding the landscape and anticipating future trends, businesses can secure a competitive edge in the market. Claim: Investing in the right packing technology today ensures sustained success in tomorrow’s competitive landscape.