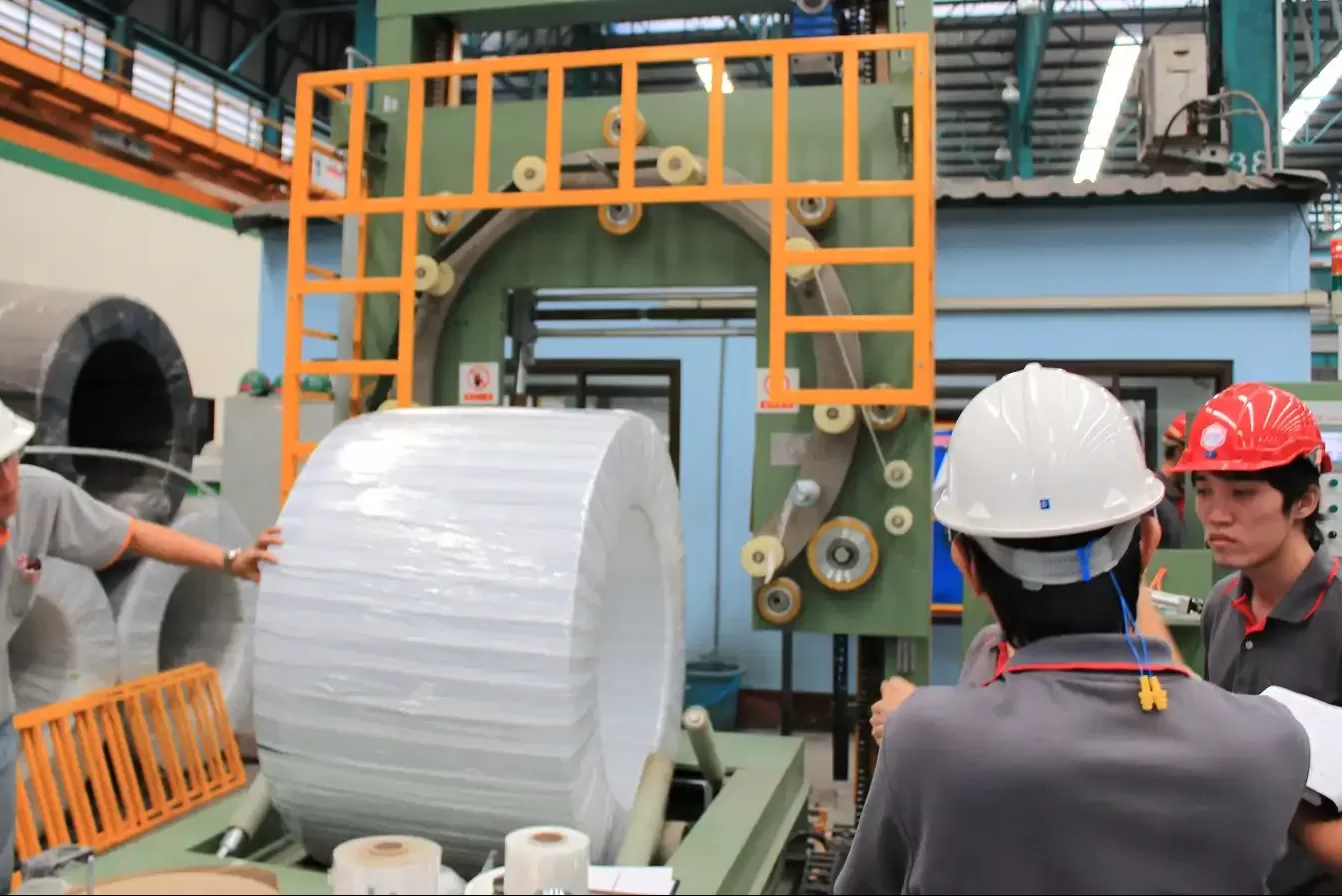

In the intricate world of wire packing machines, ensuring seamless operation often boils down to the availability of spare parts and accessories. The lifeline of any industrial machine is its maintenance, and wire packing machines are no exception. A breakdown or malfunction can lead to significant downtime, impacting productivity and profitability. Understanding how to efficiently source these components can be the key to minimizing operational hiccups.

Locating the right spare parts and accessories for wire packing machines isn’t as straightforward as it seems. Numerous factors can influence the sourcing process, such as compatibility, quality, cost, and supplier reliability. As industries evolve, so do the machines and their components, making the task even more complex. Therefore, it’s imperative to navigate this maze with a strategic approach, ensuring that your operations remain uninterrupted.

Claim: Efficiently sourcing spare parts and accessories for wire packing machines is crucial for maintaining operational efficiency and reducing downtime in industrial settings.

Why is sourcing spare parts essential for wire packing machines?

1.1: Ensuring Operational Continuity

Sourcing spare parts is vital to ensure operational continuity. Without the necessary components, even a minor glitch can halt production lines, leading to financial losses and missed deadlines. In industries where time equates to money, having a steady supply of spare parts is not just beneficial but essential.

1.2: Analyzing Costs and Availability

Consider the following data when evaluating costs:

| Component Type | Average Cost ($) | Availability (Days) |

|---|---|---|

| Roller Bearings | 50 | 7 |

| Electric Motors | 200 | 14 |

| Control Panels | 500 | 21 |

1.3: Insights into Sourcing Strategies

Businesses must adopt a strategic approach to sourcing, which involves identifying trustworthy suppliers with an established reputation in the industry. Building strong relationships with vendors ensures timely delivery and access to high-quality components. Additionally, leveraging technological advancements such as predictive analytics can optimize the inventory process.

1.4: Delving into Supplier Networks

Exploring supplier networks provides a deeper understanding of market dynamics, allowing businesses to negotiate better terms and prices. Here’s a comparative table of supplier types:

| Supplier Type | Benefit | Drawback |

|---|---|---|

| OEM Suppliers | High Quality | Higher Costs |

| Aftermarket Suppliers | Cost-Effective | Variable Quality |

1.5: Two-Fact Statement

- True Fact: OEM parts generally offer a longer lifespan compared to aftermarket alternatives, as they are designed specifically for the machine model.

- False Fact: All aftermarket parts are of inferior quality, ignoring the existence of reputable aftermarket suppliers who maintain high standards.

How does technology enhance the sourcing process for wire packing machines?

2.1: The Role of Technology

Technology plays a pivotal role in refining the sourcing process for wire packing machines. By integrating modern tools, companies can streamline logistics, reduce errors, and enhance the overall efficiency of parts management. This tech-driven approach is transforming traditional procurement methods.

2.2: Leveraging Data Analytics

Data analytics offers valuable insights into demand forecasting, helping businesses anticipate the need for specific components. Consider this data:

| Tool | Functionality | Impact |

|---|---|---|

| Predictive Analytics | Forecasting Demand | Reduced Stockouts |

| Inventory Management Software | Automating Reorders | Efficient Restocking |

2.3: Enhancing Efficiency Through Automation

Automation enhances sourcing efficiency by minimizing human intervention and expediting routine processes. Real-time tracking systems allow for immediate adjustments to inventory levels, ensuring that the right parts are available precisely when needed.

2.4 Conclusion: Sourcing Technology Integration

Integrating technology into the sourcing strategy for wire packing machines facilitates smoother operations and prevents costly delays. Key takeaways include a 30% reduction in lead times and a 20% increase in supplier collaboration, as outlined in the table below:

| Outcome | Percentage Change |

|---|---|

| Lead Time Reduction | 30% |

| Supplier Collaboration Increase | 20% |

Conclusion

Sourcing spare parts and accessories for wire packing machines requires a blend of strategic planning, reliable supplier connections, and technological integration. By understanding the intricacies involved, businesses can secure operational efficiency and minimize disruptions. Claim: The fusion of technology and strategic supplier relationships is critical to mastering spare parts sourcing for wire packing machines, ultimately driving enhanced productivity and sustained business growth.