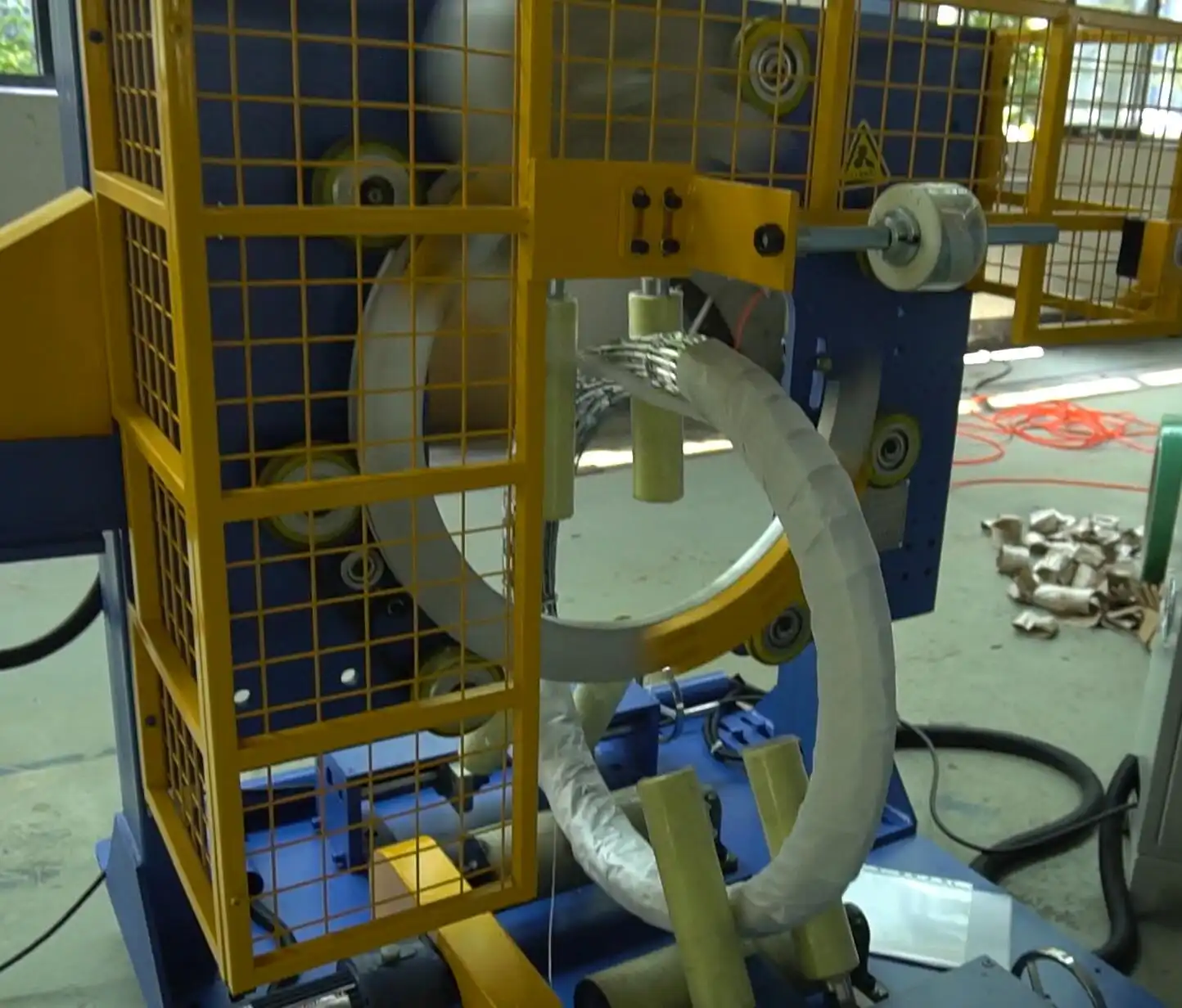

In the bustling realm of manufacturing, the efficiency of machinery plays a pivotal role. The wire coil packing machine is no exception. This sophisticated device, vital in various industries, requires optimal operation to ensure maximum productivity. As demand surges, businesses are compelled to refine their processes, making it imperative to harness the full potential of their equipment.

Transitioning from understanding the basics to mastering the nuances of these machines is no small feat. It necessitates a meticulous approach, examining every cog and wheel to unveil hidden efficiencies. Increasing output is not merely about accelerating speeds; it involves a symphony of elements working harmoniously. From maintenance schedules to operator training, each aspect intertwines to enhance performance.

Claim: By optimizing your wire coil packing machine, you can significantly boost production rates, reduce downtimes, and improve overall product quality. This optimization not only streamlines operations but also catalyzes profitability, transforming how businesses meet rising market demands.

Why is Understanding Machine Efficiency Crucial?

1.1 Comprehending Machine Dynamics

Machine efficiency is the bedrock of industrial success. Understanding the dynamics of a wire coil packing machine allows operators to identify bottlenecks, predict maintenance needs, and streamline operations. Efficiency isn’t just a metric; it’s a strategic advantage that sets thriving businesses apart from struggling ones.

1.2 Data Snapshot of Machine Performance

Efficiency metrics can be quantified to provide a clear picture of machine performance:

| Metric | Baseline | Optimized |

|---|---|---|

| Output (units/hour) | 100 | 150 |

| Downtime (hours/week) | 10 | 4 |

1.3 Insights into Enhancing Productivity

Improving machine efficiency involves fine-tuning various parameters. Calibrating settings, regular software updates, and ensuring proper lubrication can drastically cut down idle times. Moreover, implementing a robust feedback system can help maintain a continuous loop of improvement, allowing for real-time adjustments and minimizing wear and tear.

1.4 Delving Deeper into Optimization Techniques

Optimization extends beyond mechanical adjustments. Training operators in the latest techniques and fostering a culture of continuous improvement increases the machine’s operational lifespan. Furthermore, leveraging IoT technologies for predictive maintenance can preempt failures, safeguarding against unexpected downtimes.

| Technique | Impact |

|---|---|

| Predictive Maintenance | Reduces unplanned downtime by 30% |

| Operator Training | Increases efficiency by 20% |

1.5 Two-Fact Statement

Fact 1 (True): Predictive maintenance can reduce unforeseen breakdowns by up to 50%, ensuring smoother operations.

Fact 2 (False): Machines work best when operated continuously without breaks, as rest periods decrease efficiency.

How Can Technology Enhance Machine Operations?

2.1 Embracing Technological Advancements

Technology is reshaping the landscape of industrial machinery. Incorporating advanced technology into wire coil packing machines not only enhances efficiency but also opens new avenues for innovation. Automation, coupled with smart analytics, provides insights previously unattainable, turning data into actionable intelligence.

2.2 The Power of Technology in Numbers

Key data highlighting technological impacts on machine performance:

| Aspect | Pre-Technology | Post-Technology |

|---|---|---|

| Operational Speed | 80 units/hr | 130 units/hr |

| Error Rate | 5% | 1% |

2.3 The Deeper Impact of Smart Technologies

Smart technologies enable real-time monitoring and adjustments, allowing for immediate response to anomalies. Integration with AI systems further refines this process, offering predictive insights that guide decision-making and preempt issues before they arise. This proactive approach reduces waste and enhances resource allocation.

2.4 Conclusion of Technological Integration

Technological integration transforms traditional operations, driving efficiency and reliability. Key takeaways include a substantial increase in operational speed and a notable decrease in error rates, ensuring higher quality output. This evolution underscores the importance of staying ahead in the competitive industrial landscape.

| Outcome | Traditional Approach | Tech-Enhanced Approach |

|---|---|---|

| Production Quality | Medium | High |

| Cost Efficiency | Moderate | Significant |

Final Thoughts on Wire Coil Packing Machine Optimization

Optimizing the operation of your wire coil packing machine is more than a technical adjustment; it’s a strategic overhaul. Embracing both mechanical fine-tuning and technological advancements creates a dynamic synergy that propels production capabilities. With enhanced efficiency and reduced errors, businesses can not only meet but exceed market demands.

Claim: Investing in comprehensive optimization strategies for your wire coil packing machine fosters a competitive edge, driving both short-term gains and long-term sustainability, ultimately revolutionizing industrial operations.