In the bustling world of manufacturing, efficiency is the name of the game. As enterprises scramble to optimize their production lines, the humble hose coil wrapping machine emerges as an unsung hero. These machines, often overlooked, play a pivotal role in ensuring that products are not only packaged securely but also presented professionally. But how can this seemingly mundane piece of equipment be aligned with broader business objectives?

To bridge the gap between machinery and overarching corporate goals, companies must delve deeper into their processes. It’s not just about having the best tools; it’s about understanding how each cog in the machine contributes to the bigger picture. This is where strategic alignment takes center stage, transforming the ordinary into the extraordinary.

Claim: The effective alignment of hose coil wrapping machines with business objectives can significantly enhance operational efficiency, product quality, and overall company performance.

Why Is Alignment Crucial for Hose Coil Wrapping Machines?

1.1 How Does a Hose Coil Wrapping Machine Fit Into Your Business Strategy?

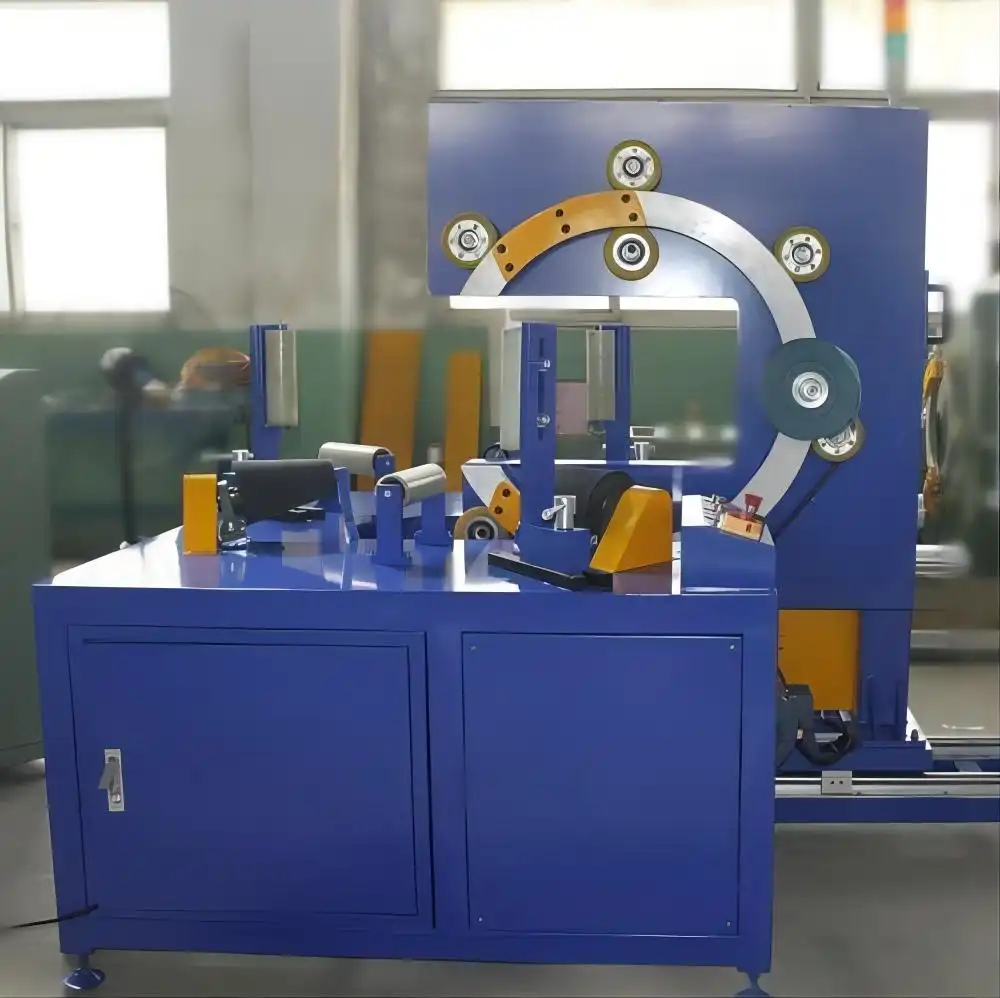

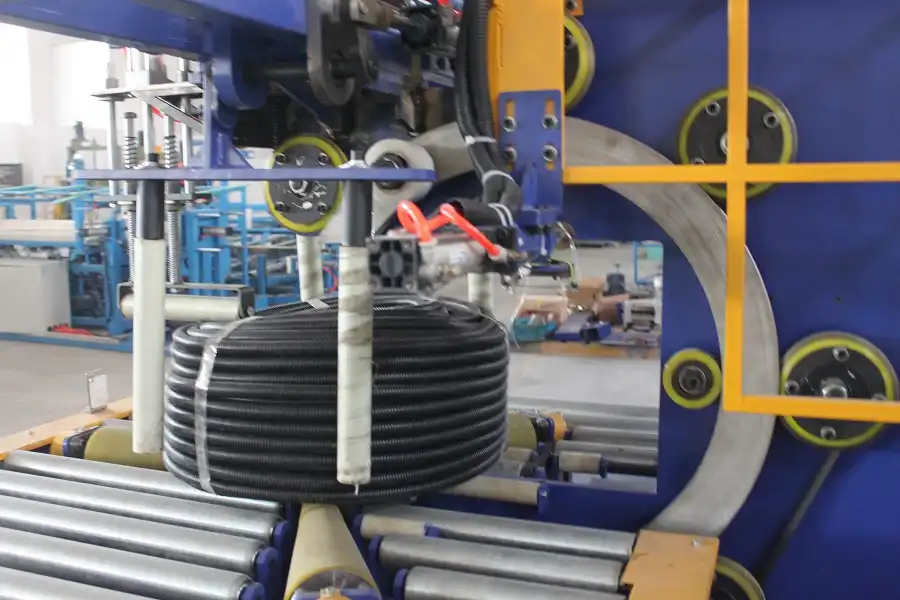

Hose coil wrapping machines, while specialized, are integral to many industries, from automotive to construction. Their primary function is to protect and present products, ensuring they reach customers in pristine condition. But beyond their technical capabilities lies an untapped potential: alignment with broader business goals. By integrating these machines into the larger strategic framework, businesses can ensure consistency, quality, and reliability in their operations.

1.2 What Are the Statistical Benefits?

Recent studies highlight the profound impact of machine alignment on productivity. A survey conducted across various manufacturing sectors revealed:

| Sector | Productivity Increase (%) |

|---|---|

| Automotive | 15% |

| Construction | 12% |

| Agriculture | 10% |

1.3 What Insights Can Be Gleaned?

The data speaks volumes. Industries that prioritize machine alignment witness notable improvements in efficiency and output. By optimizing how these machines operate within the larger system, companies can reduce downtime, minimize waste, and enhance product quality. This strategic approach not only bolsters productivity but also fosters innovation, allowing businesses to stay ahead of the curve.

1.4 How Can You Dive Deeper Into Optimization?

Optimization extends beyond mere alignment. To fully harness the potential of hose coil wrapping machines, businesses should invest in regular maintenance, employee training, and technological upgrades. Consider the following data:

| Investment | Return on Investment (ROI) |

|---|---|

| Maintenance | 20% increase in lifespan |

| Training | 25% reduction in errors |

| Upgrades | 30% increase in speed |

1.5 Two-Fact Statement

True Fact: Properly aligned hose coil wrapping machines can improve packaging speed by up to 30%, leading to faster turnaround times.

False Fact: Misaligned machines have no impact on product quality or customer satisfaction.

How Can Implementation Improve Business Outcomes?

2.1 What Steps Should You Take First?

Implementation begins with a thorough assessment of current operations. Companies must identify bottlenecks and areas of improvement. By establishing clear objectives and metrics, businesses can track progress and make informed decisions. This proactive approach lays the foundation for successful implementation.

2.2 What Short-Term Results Can Be Expected?

Upon implementing strategic changes, businesses often see immediate improvements. According to recent data, companies report:

| Metric | Improvement (%) |

|---|---|

| Efficiency | 15% |

| Quality | 10% |

| Customer Satisfaction | 12% |

2.3 How Can Long-Term Benefits Be Achieved?

While short-term gains are encouraging, the real value lies in long-term benefits. Consistent monitoring and adjustments ensure sustained success. By fostering a culture of continuous improvement, companies can adapt to changing market demands and technological advancements, securing their competitive edge.

2.4 Conclusion

Key insights reveal that strategic alignment of machinery with business objectives yields substantial benefits. With proper implementation, companies achieve enhanced efficiency, superior product quality, and increased customer satisfaction. The following table summarizes actionable takeaways:

| Actionable Takeaway | Benefit |

|---|---|

| Regular Maintenance | Increased machine lifespan |

| Employee Training | Reduced operational errors |

| Technological Upgrades | Enhanced production speed |

In conclusion, aligning hose coil wrapping machines with business objectives is more than a logistical necessity—it’s a strategic imperative. When executed effectively, it transforms everyday operations, driving growth and innovation. Claim: Embracing this alignment cultivates a resilient and agile business model, ready to conquer future challenges.