In the labyrinth of modern manufacturing, where precision meets efficiency, the choice of machinery can be the thin line between success and setback. Enter the realm of cable coil packing machines—those unsung heroes tasked with bundling the intricate threads of technology into cohesive wholes. As globalization stitches together diverse markets, the demand for streamlined operations surges, spotlighting the need for adept machinery selection.

The journey to procure the perfect cable coil packing machine is akin to navigating a maze; it necessitates not only understanding technical specifications but also foreseeing future needs. This process, rich in complexity, involves evaluating myriad factors from speed to adaptability, each playing a pivotal role in ensuring operational efficacy. The stakes are high, making the selection an endeavor that demands both foresight and innovation.

Claim: Choosing the right cable coil packing machine is imperative for optimizing production efficiency, reducing costs, and maintaining product integrity in the highly competitive manufacturing landscape.

What Are the Key Features to Look for in a Cable Coil Packing Machine?

1.1 Understanding Core Features

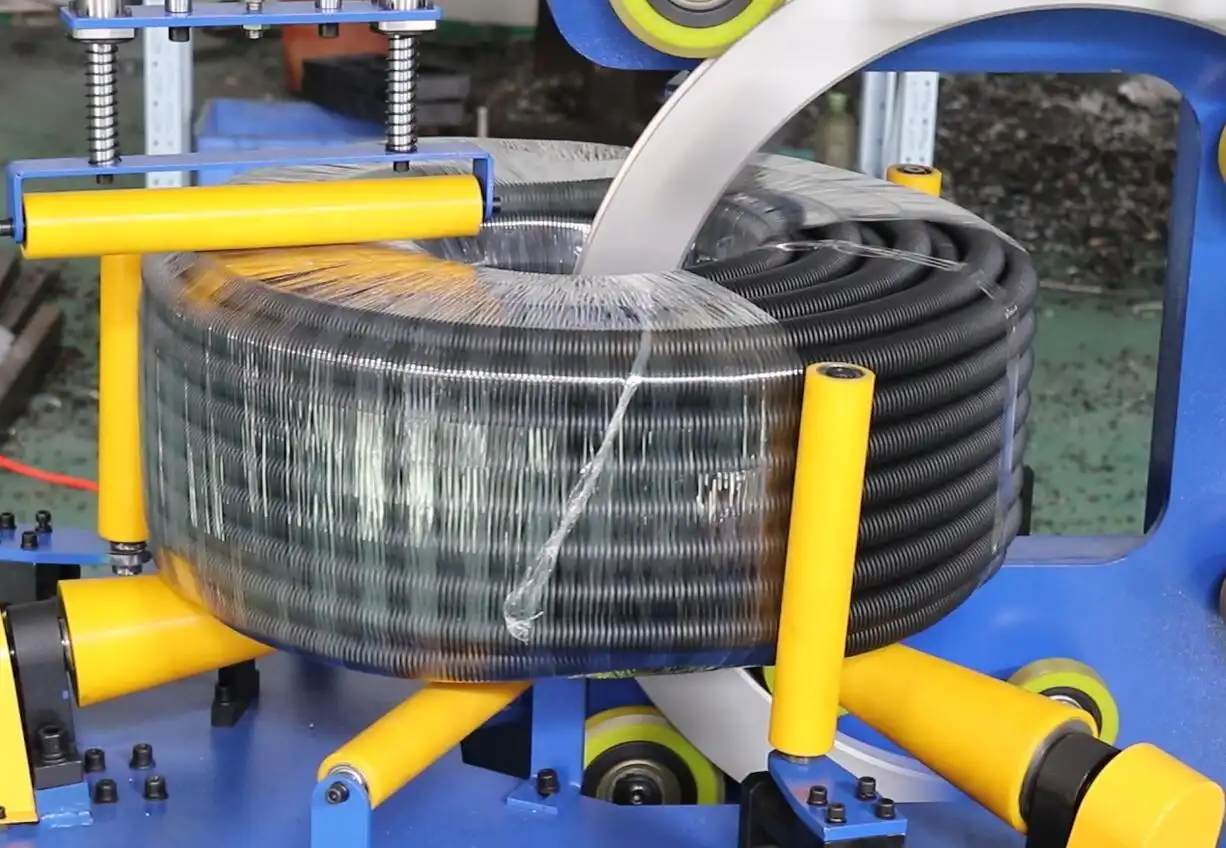

When assessing a cable coil packing machine, it’s essential to focus on core features such as speed, automation level, compatibility with various cable sizes, and reliability. High-speed models cater to large-scale operations, while automation enhances productivity by minimizing manual intervention. Additionally, machines boasting multi-size compatibility offer flexibility, an invaluable asset in diverse manufacturing environments.

1.2 Feature Comparison Table

Choosing the right machine involves comparing technical specifications. The table below outlines essential features and their variations among different models.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Speed (coils/hour) | 500 | 750 | 600 |

| Automation Level | Semi-automatic | Fully automatic | Semi-automatic |

| Cable Size Compatibility | Multiple | Multiple | Single |

1.3 Insights into Operational Efficiency

A nuanced understanding of how these features interplay can significantly elevate operational efficiency. Machines with higher speed ratings can swiftly adapt to ramped-up production demands, while fully automated systems reduce human error, enhancing consistency across outputs. Multi-size compatibility ensures seamless transitions between different production batches, saving time and resources.

1.4 Delving Deeper: Cost vs. Benefit Analysis

The cost-benefit dynamic of cable coil packing machines influences the decision-making process. While high-speed, fully automated models might carry a premium price tag, they often yield long-term savings through heightened productivity and decreased downtime. Below is a comparative analysis of investment costs versus potential returns.

| Model | Initial Investment | Potential Annual Savings | ROI (%) |

|---|---|---|---|

| Model A | $50,000 | $20,000 | 40% |

| Model B | $70,000 | $30,000 | 43% |

| Model C | $60,000 | $25,000 | 42% |

1.5 Two-Fact Statement

True Fact: Fully automated cable coil packing machines typically result in lower labor costs and increased throughput.

False Fact: All cable coil packing machines are equally efficient regardless of their automation levels, which is misleading as semi-automatic machines require more manual oversight.

How Does Technology Impact the Future of Cable Coil Packing?

2.1 Embracing Technological Advancements

The technological evolution within cable coil packing machines heralds a new era of efficiency and innovation. Integration of IoT and AI technologies is transforming traditional machinery into smart solutions capable of predictive maintenance and real-time monitoring, thus significantly reducing downtime and enhancing precision.

2.2 Technological Advancements Snapshot

Here’s a snapshot of current technological advancements influencing cable coil packing:

| Technology | Impact |

|---|---|

| IoT | Enables real-time monitoring and remote diagnostics |

| AI | Facilitates predictive maintenance, reducing unexpected downtimes |

| Advanced Sensors | Enhances precision and decreases material waste |

2.3 Future Impact of Technology

As technology continues to advance, the potential for even greater efficiency within cable coil packing operations becomes apparent. Predictive analytics, driven by AI, offers unprecedented foresight into maintenance needs, thereby minimizing disruptions. Similarly, IoT provides actionable insights, streamlining processes and ensuring optimal resource utilization.

2.4 Conclusion: Harnessing Technology

To harness these emerging technologies effectively, manufacturers must invest strategically in upgrading existing machinery or acquiring new models equipped with cutting-edge tech. The following table summarizes key actionable steps alongside their expected outcomes.

| Action | Expected Outcome |

|---|---|

| Upgrade Existing Machinery | Improved efficiency, reduced manual errors |

| Invest in Smart Machines | Enhanced production capabilities, real-time insights |

By embracing these advancements, companies can stay ahead of the curve, ensuring long-term sustainability and competitiveness.

Conclusion

The selection of a cable coil packing machine is far more than a procurement decision; it is a critical strategic choice impacting every facet of production. By considering essential features, analyzing costs against benefits, and embracing technological innovations, businesses can ensure their operations remain at the forefront of efficiency and efficacy.

Final Claim: In the rapidly evolving industrial landscape, the right cable coil packing machine embodies the heart of operational success, driving forward industry standards and innovation.