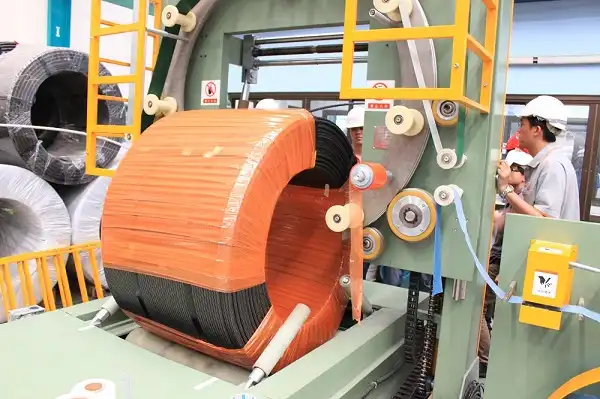

Automation is more than just a buzzword; it’s a transformative force sweeping across industries, reshaping processes with precision and efficiency. One area undergoing significant change is the wire coil wrapping sector. Here, automation is not only pushing boundaries but also redefining how companies approach production.

As industries strive for greater efficiency and reduced human error, wire coil wrapping machines are evolving with automated technologies at their core. The advent of these systems marks a new era where manual labor meets robotic precision. This blend creates an efficient workspace that maximizes productivity while ensuring quality consistency.

Claim: The integration of automation into wire coil wrapping machines enhances production by increasing speed, improving safety, and ensuring consistent output, making it an indispensable asset in modern manufacturing.

What Are the Benefits of Automating Wire Coil Wrapping Machines?

Enhanced Speed and Efficiency

Incorporating automation into wire coil wrapping machines significantly boosts operational speed. Automated systems handle tasks that would take considerably longer if performed manually, allowing factories to increase their throughput. These machines can operate continuously without fatigue, maintaining a steady pace that humans cannot match consistently.

Performance Metrics of Automated vs. Manual Systems

When comparing the performance of automated and manual wire coil wrapping systems, the differences are stark. Consider the following data:

| Parameter | Automated System | Manual System |

|---|---|---|

| Speed (units/hour) | 150 | 60 |

| Error Rate (%) | 0.5 | 5.0 |

| Labor Cost (% of total cost) | 20 | 40 |

Insights on Increased Productivity

Automation enhances not only the speed but also the reliability of the production process. By minimizing errors and reducing the need for constant human intervention, companies experience fewer interruptions. This continuity allows for meeting higher production targets and deadlines, thereby positively impacting overall business growth.

Delving into Cost-Savings and ROI

The initial investment in automated wire coil wrapping machines may seem substantial, yet the return on investment (ROI) quickly becomes evident. Labor costs decrease as fewer workers are required for operation, and energy-efficient machinery reduces utility expenses. Here’s a table illustrating potential savings:

| Cost Component | Automated | Manual |

|---|---|---|

| Annual Labor Expenses | $50,000 | $100,000 |

| Operational Costs | $15,000 | $25,000 |

| ROI (over 5 years) | 75% | 20% |

Two-Fact Statement

True Fact: Automated wire coil wrapping machines can operate 24/7 with minimal supervision, leading to significant productivity gains.

False Fact: Automation in wire coil wrapping machines eliminates all labor costs, making human oversight unnecessary. In reality, skilled technicians are still needed to program, maintain, and troubleshoot the machines.

How Does Automation Affect Safety and Quality Assurance?

The Safety Benefits of Automation

One of the most compelling advantages of automation in wire coil wrapping is enhanced safety. Machines equipped with advanced sensors can detect anomalies and prevent accidents, protecting both employees and equipment from harm. This technology reduces the frequency of workplace injuries, contributing to a safer working environment.

Safety Metrics and Improvements

Safety improvements in automated systems are quantifiable. Here’s a look at how automation impacts safety metrics:

| Safety Metric | Automated System | Manual System |

|---|---|---|

| Injury Rate (per 100 workers) | 1.2 | 4.8 |

| Incident Response Time (minutes) | 2 | 10 |

Quality Assurance Through Automation

Quality assurance is another area where automation shines. Consistent output quality is achieved through precise and repeatable processes, reducing waste and ensuring customer satisfaction. Automated systems are less prone to the variability that plagues manual operations, resulting in uniform product quality.

Conclusion: Actionable Insights and Takeaways

By embracing automation in wire coil wrapping machines, manufacturers can achieve a harmonious balance between productivity and quality. Key insights include: automated systems offer a significant reduction in labor and operational costs, improve workplace safety, and ensure consistent product quality. The following table summarizes these points:

| Insight | Impact |

|---|---|

| Cost Reduction | Significant long-term savings |

| Safety Enhancements | Reduced injury rates |

| Quality Consistency | High customer satisfaction |

Conclusion

In conclusion, automation in wire coil wrapping machines represents a pivotal advancement in manufacturing, offering unparalleled benefits in speed, safety, and quality assurance. Organizations looking to stay competitive in today’s fast-paced market must consider this transition. Claim: Automation is no longer an option; it is a necessity for achieving operational excellence and sustained growth in the industry.